- What is Laser Cutting?

- What materials can be cut with a Laser?

- Advantages of choosing laser metal cutting

- What types of laser cutting machines are popular today?

- Working principle of laser cutting machine for metal

- Some main software supporting Laser cutting

- Learn the difference between laser engraving and cutting

- Application of Laser cutting technology in life

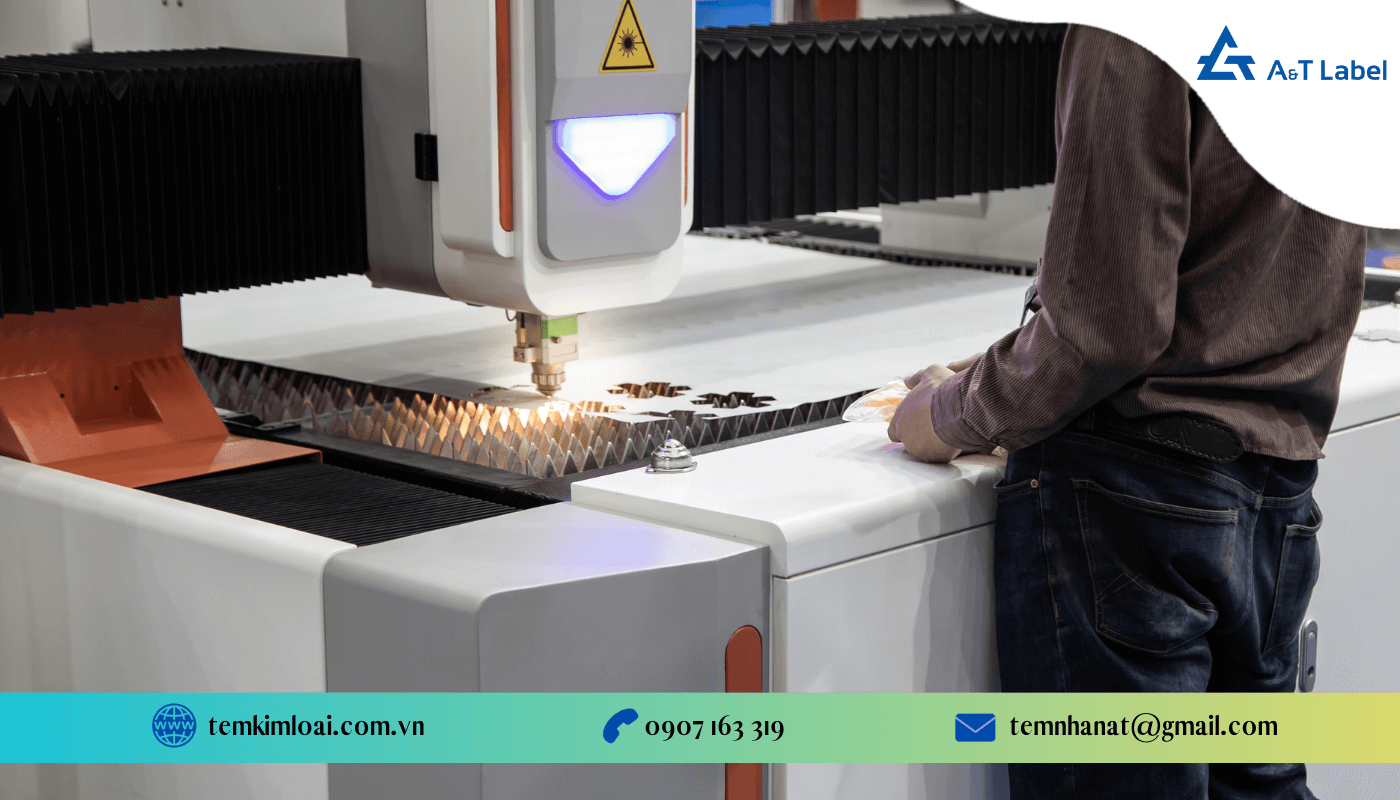

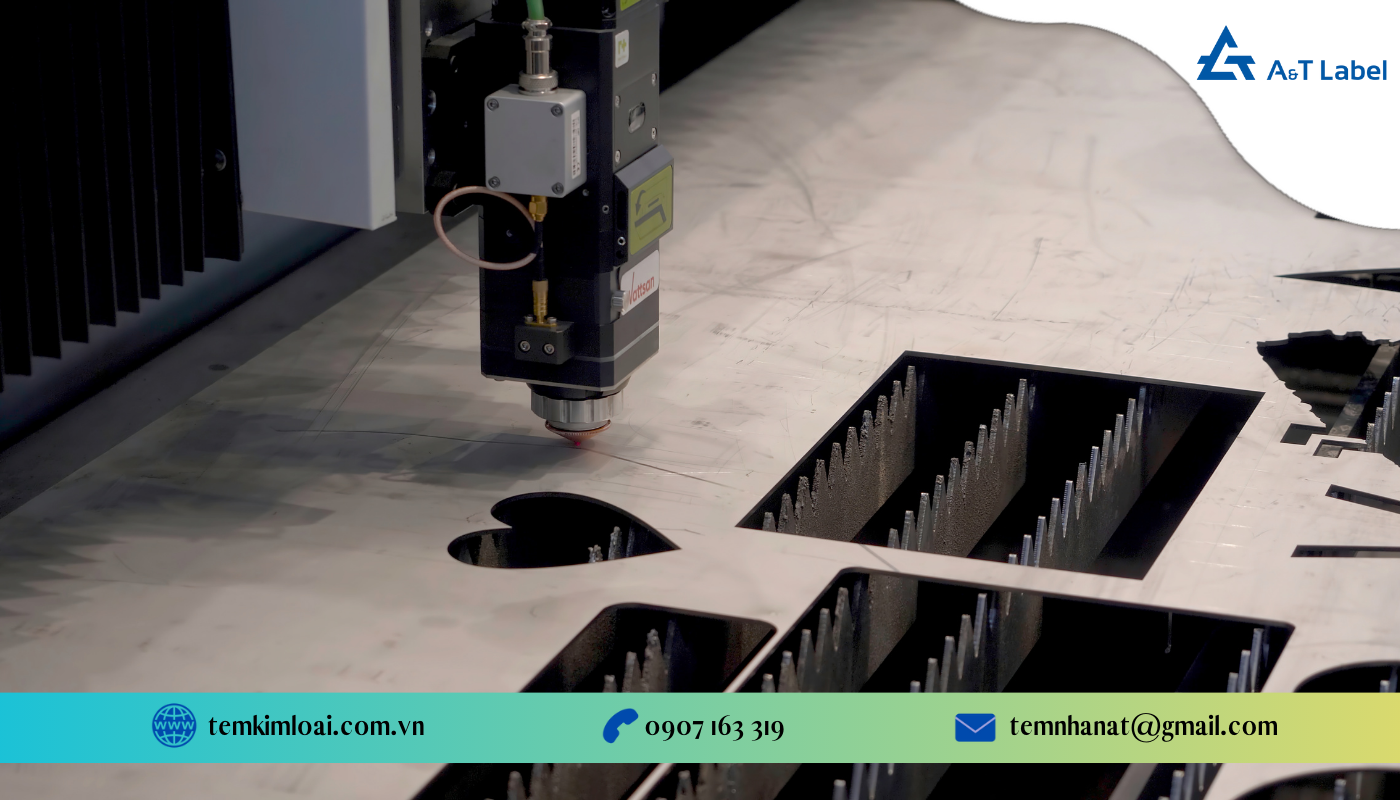

What is Laser Cutting?

Laser cutting is the process of using a laser beam focused at a point to melt the material and create different pre-set material shapes. Laser cutting technology can be used on many materials such as glass, wood or metals such as iron, steel, stainless steel, copper, aluminum, etc.

Laser cutting technology is considered a big step forward in the field of mechanics, and is also the most advanced technology today. The application of laser cutting machines in the processing process contributes to creating sophisticated and beautiful details for products. Therefore, this technology is also widely used in many fields.

What materials can be cut with a Laser?

In fact, lasers can cut almost any material from metal to non-metal. For metal processing, laser cutting machines can cut stainless steel, iron, carbon steel, copper, aluminum from 2 – 50mm thick. However, depending on each type of material, the ability to process laser cutting is different.

Iron, carbon steel and stainless steel are the easiest metal materials to cut with a laser. For alloy steels such as AISI 4140, 8620, SUS304, SS304, SUS201… the machine can cut with a thickness of up to 20mm. The higher the alloy content in the steel, the more difficult the cutting process will be, often causing the cutting speed to slow down and there will be slag.

In addition, aluminum and pure copper are two materials that are very difficult to cut with a laser because they have the ability to reflect the laser beam strongly. During the cutting process, the amount of heat transferred to the copper and aluminum parts is very large and fast, while both of these materials cannot withstand high temperatures, which can easily lead to the risk of the material bending. Therefore, it is important to adjust the laser focus accurately to avoid the laser beam reflecting back to the laser spray system too strongly, causing damage to the optical components.

Advantages of choosing laser metal cutting

Using Laser to cut materials is one of the most popular methods in the metal forming industry thanks to the following advantages:

- Can process on many different materials such as metal, non-metal, plastic, copper, aluminum, stainless steel, paper cutting…;

- Small Laser cutting tolerance with high precision;

- Can be arbitrarily deformed;

- Fast cutting speed helps increase production efficiency many times compared to traditional cutting methods;

- Reasonable price, even cheaper than many other methods when cutting in large quantities;

- High quality cutting groove with extremely short Laser pulse, helps the surface smooth and beautiful without having to clean the cutting surface after processing.

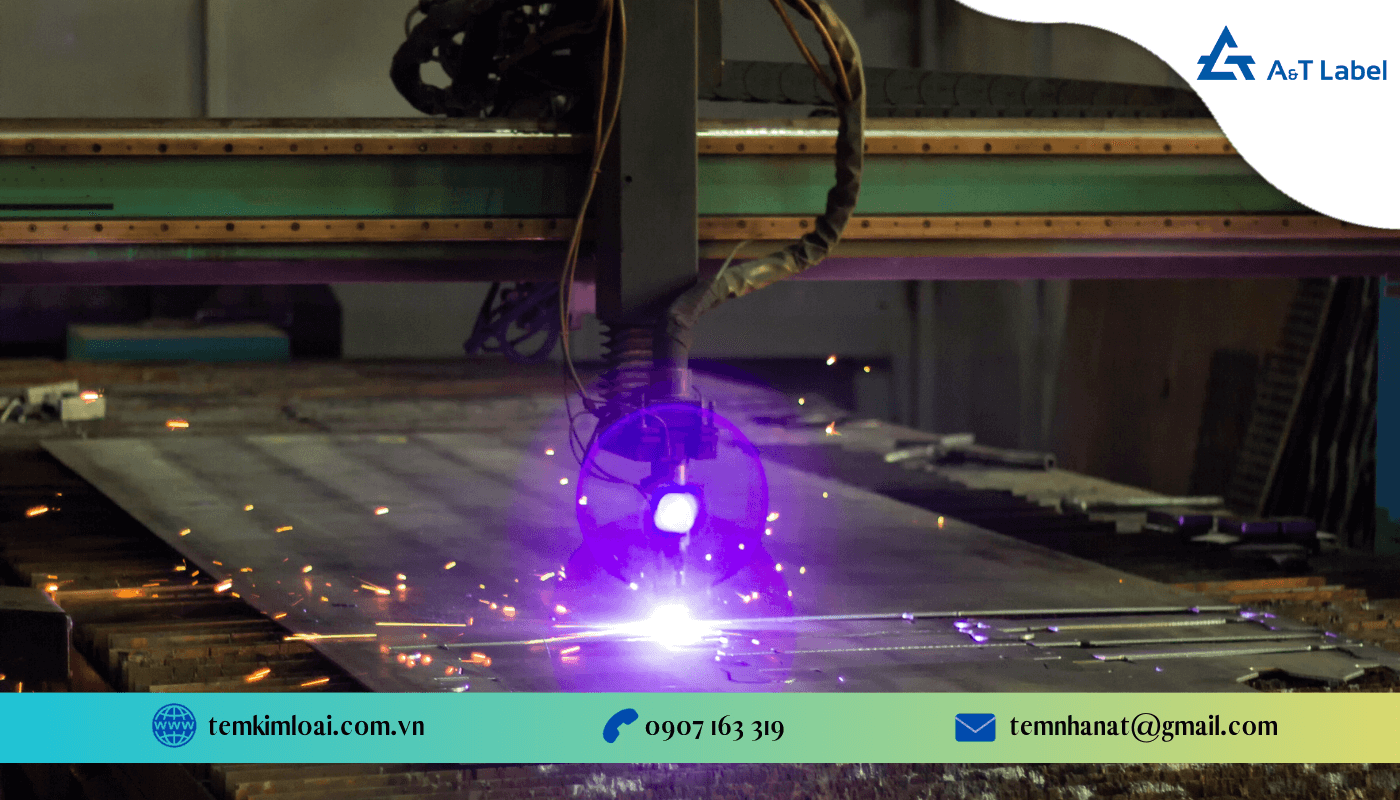

What types of laser cutting machines are popular today?

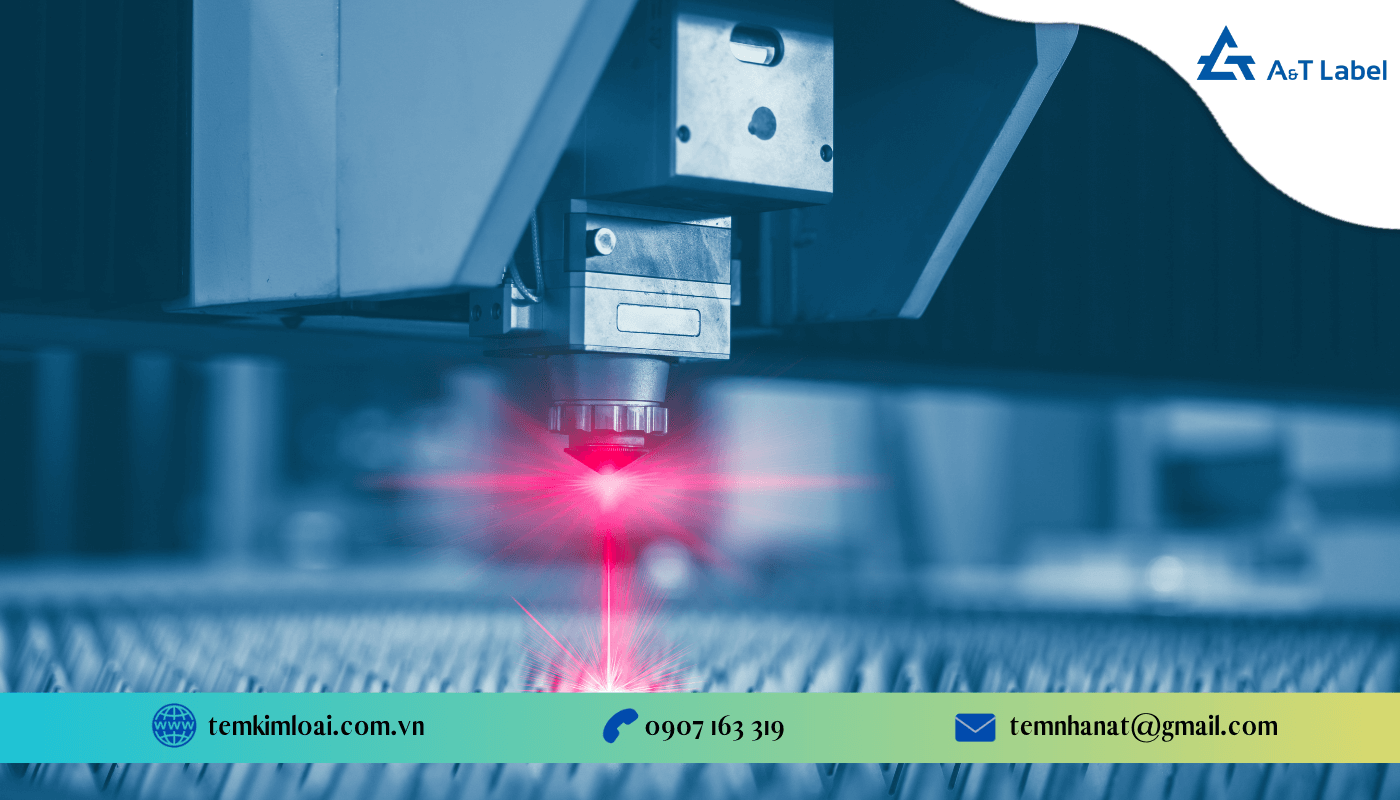

Currently, laser cutting machines are divided into 3 main types based on the laser source used:

- CO2 Laser Cutting Machine: This is a machine that uses a gas laser source. CO2 Laser Cutting Machine is the most popular type of machine today and is also a highly applicable technology when it can cut materials with large thickness. The operating principle of this machine is to use a mixture of electrically stimulated Carbon Dioxide gas to create force on the material. The advantages of this type of machine are low cost, high precision, and the ability to cut and rasterize a number of materials.

- Fiber Laser Cutting Machine: This is a cutting machine that uses a laser source from an optical fiber, which belongs to the solid-state laser group and is the technology that produces the highest quality products today. The operating principle of the machine is to create an amplified laser beam in a special glass fiber that is powered by a pump diode. In addition to fast cutting speed, the fiber laser cutting machine also has the outstanding advantage of being able to process highly complex details thanks to the beam with an ultra-small focal diameter.

- Crystal Laser Cutting Machine: Similar to Fiber Laser Cutting Machine, Crystal Laser Machine also uses solid-state Laser and marks on materials by pumping Laser directly from diodes, in which the commonly used Laser sources are YAG and Nd. The outstanding advantage of Nd and YAG Lasers is that they can be emitted in pulse mode and continuous mode, creating extremely large power up to hundreds of megawatts.

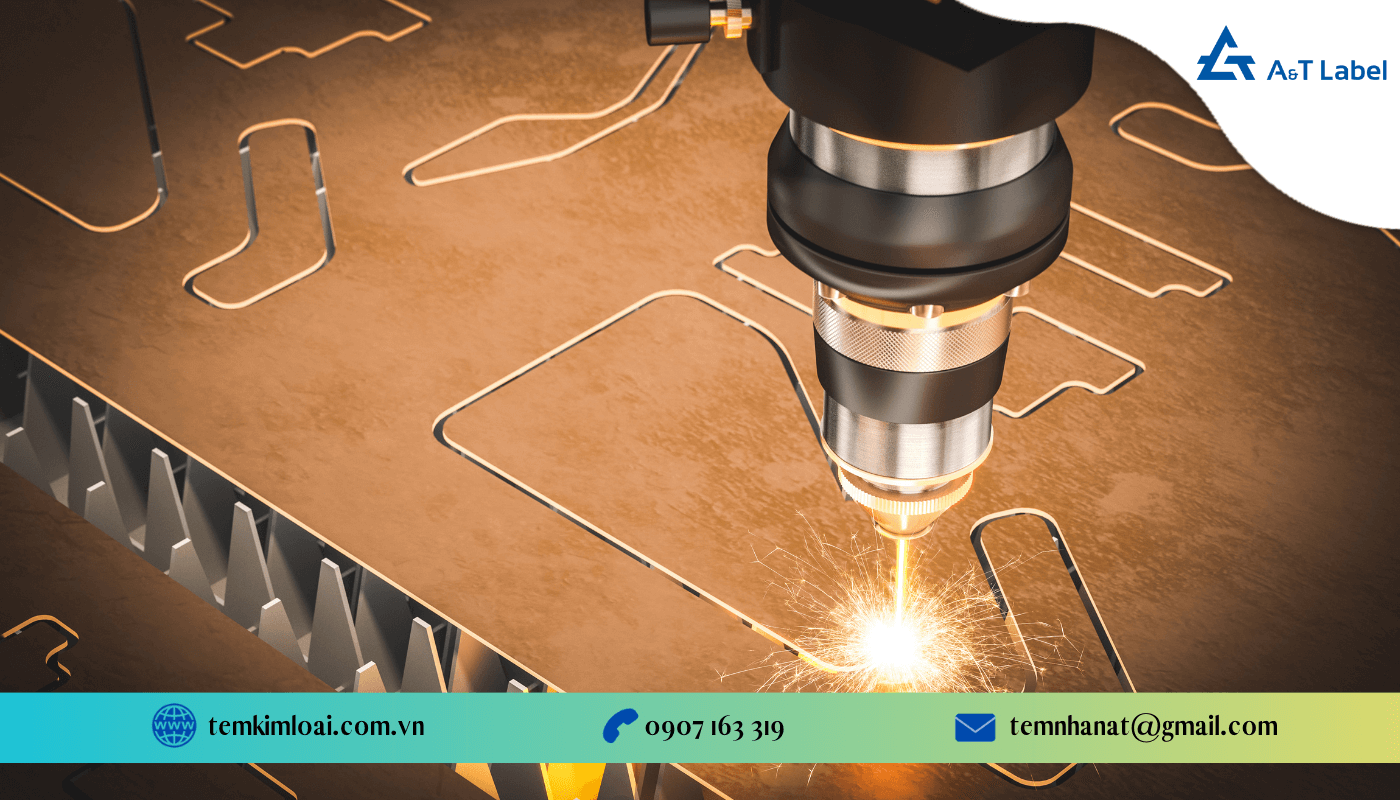

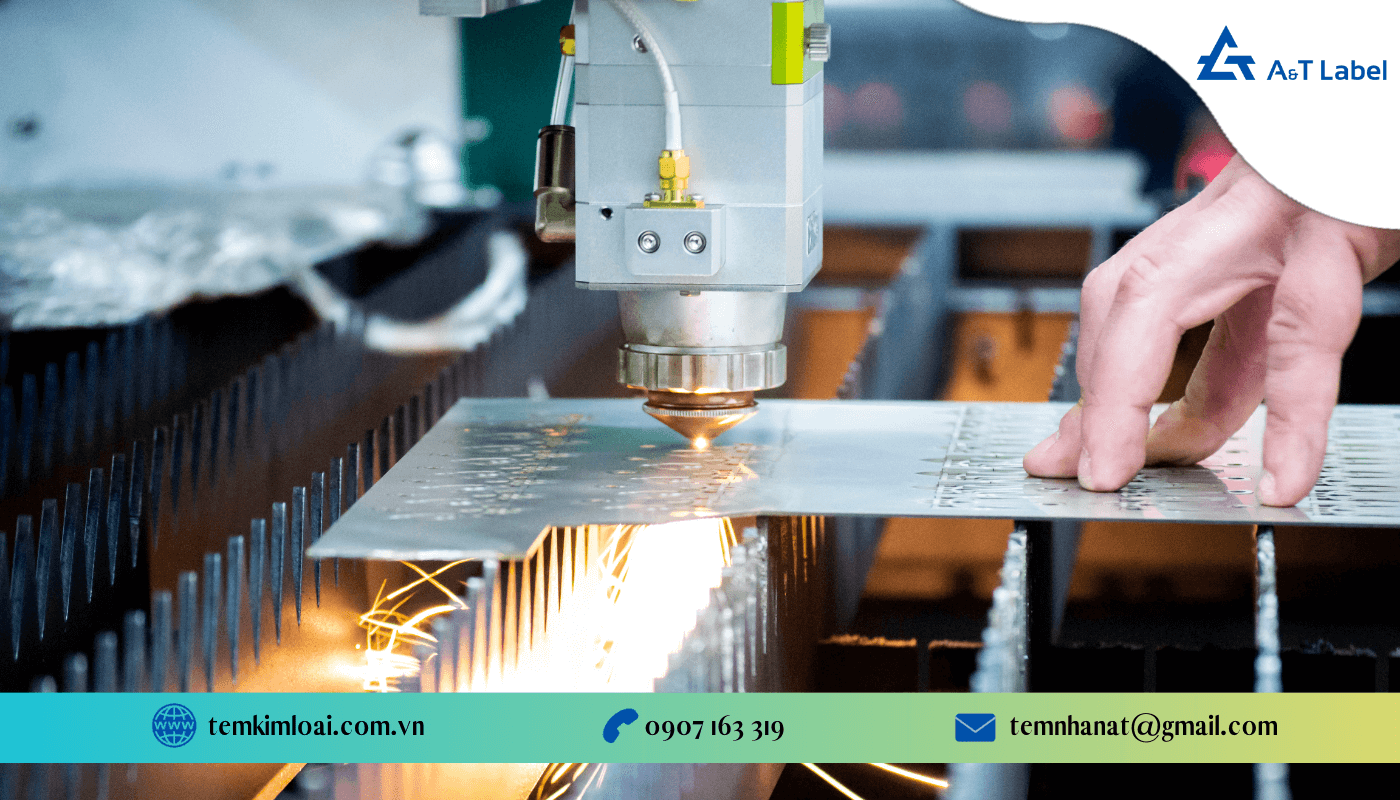

Working principle of laser cutting machine for metal

The basic working principle of a metal laser cutting machine is to use a laser beam to melt the metal and create a cut. This laser beam is generated from a source with high energy and temperature, then converged into a small point that is projected onto the surface of the metal workpiece. The heat from the laser will melt the metal at the projection point, then use a high-pressure air stream to blow the molten metal out of the cutting groove.

Normally, the Laser cutting machine will be pre-programmed and when operating the machine, the cut will be formed based on the drawing that the machine has been programmed in advance. Depending on the cutting technology of burning or melting, the gas supplied will be O2, N2 or Argon. This will be decisive for the quality of the cutting circuit on each product.

Some main software supporting Laser cutting

To support the process of designing and operating a laser cutting machine effectively, it is certainly indispensable to have the corresponding software. These applications not only help design laser cutting patterns but also allow users to customize settings on the cutting machine including cutting style, identifying cutting areas through color and lines. If you use sample file libraries, you also need to combine additional software to read the files and edit when necessary.

Below are some popular Laser cutting support software that you can refer to:

- For 2D design: AutoCAD, Inkscape, Adobe, Illustrator, CorelDraw.

- For 3D design: Autodesk Inventor, Solidworks, Autodesk Fusion 360.

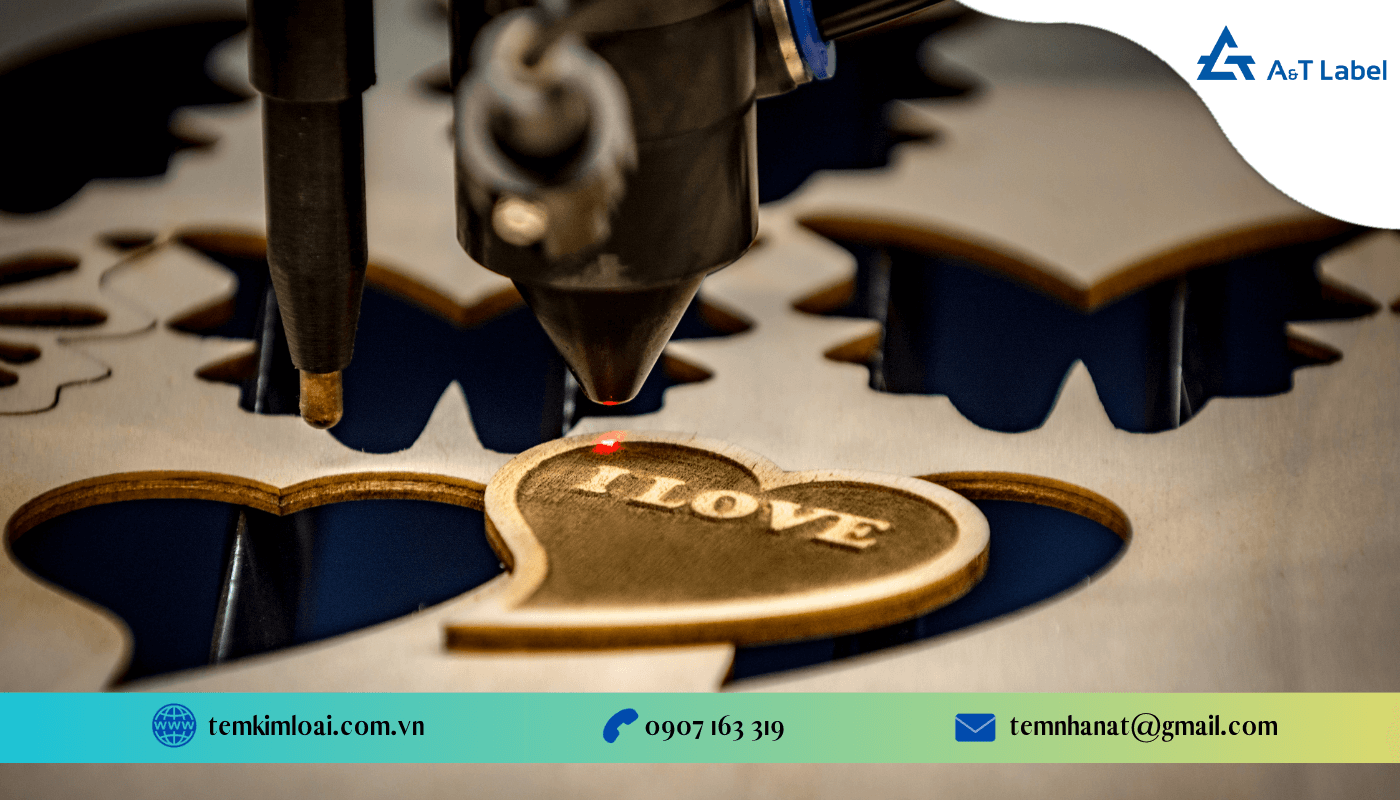

Learn the difference between laser engraving and cutting

Laser engraving and Laser cutting are both known as processing processes that use laser beams to shape materials. So how are laser engraving and cutting technologies different?

- Working principle: This is the most basic difference between Laser engraving and cutting technology. Laser cutting works on the principle of using a laser beam to cut through the material by melting, burning and evaporating. Laser engraving only uses a laser beam to engrave to the desired depth without having to cut the entire thickness of the material. Therefore, Laser engraving technology can only make the surface of the engraved material erode at a certain depth.

- Depth: Laser cutting depth is equal to the thickness of the material, as the laser beam needs to cut through the entire thickness of the material. Meanwhile, laser engraving depth is much smaller than the thickness of the material, as the laser beam only needs to engrave on the surface of the material.

- Lens Focal Length: Lens focal length is the distance from the lens to the surface of the material. Lens focal length will affect the depth and width of the cut/engrave on the material. Basically, the lens focal length of a Laser cutter will be larger than that of a Laser engraver, because it has to cut through the entire thickness of the material.

- Cutting speed: Cutting speed will affect the time and efficiency of the cutting/engraving process on the material. Laser cutting machines usually have much faster cutting speeds than Laser engraving machines, because the Laser beam has a higher power, which can cut through the thickness of the material quickly.

- Application: Laser engraving is commonly used to create images, text or symbols on the surface of materials, whereas Laser cutting is commonly used to create more complex shapes and components for materials.

With the high aesthetics and precision of Laser cutting technology, they are widely used in the production of metal labels such as speaker labels, wine labels and scratched aluminum labels…

Application of Laser cutting technology in life

Laser cutting technology is an advanced processing technology with many outstanding advantages such as:

- High precision, sharp cutting groove;

- Fast cutting speed;

- Can cut complex shapes and details;

- Easy to control and program.

Thanks to its high efficiency and cost savings, Laser cutting technology has been widely applied in many areas of life. Below are some common practical applications of Laser cutting technology:

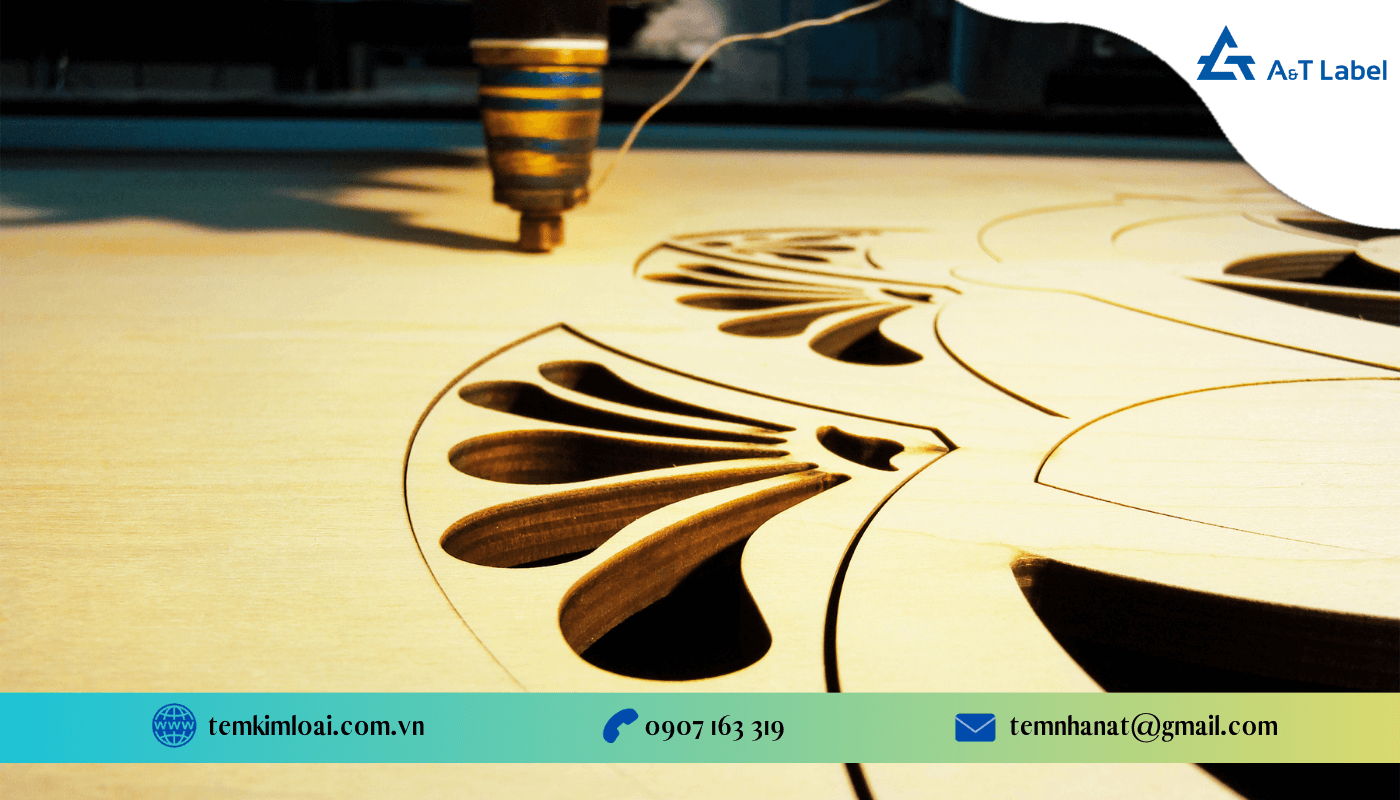

- Mechanical manufacturing: With the ability to cut sheet metal lasers, it is possible to create machine parts such as molds, frames, shells, etc. or cut metal components such as screws, bolts, etc.

- Construction: Laser cutting of steel railings, structural column trusses, sunshades, hinges, decorative motifs, etc.

- Electronic components manufacturing: Laser cutting to cut printed circuit boards and electronic components such as chips, transistors, etc.

- Interior decoration: Laser cutting technology is used to cut materials such as wood, plastic, glass, etc. and process interior decoration products such as paintings, lamps, furniture, etc. In particular, Laser cutting technology can sculpt complex details on many materials to create unique wooden paintings or art glass panels.

- Handicrafts: Processing handicraft products such as jewelry, souvenirs, etc.

In addition, Laser processing technology is also applied in many other industries such as: Laser cutting of micro cards, medical equipment, aerospace, communications, military and defense, plumbing and air conditioning systems or Laser cutting for labels, combining CNC cutting of corroded stainless steel labels with Laser technology to prevent labels from staining… It can be seen that Laser cutting technology brings many great benefits to society and will continue to develop more strongly in the future.

A&T Label hopes that this article has provided you with useful information in the process of learning about advanced Laser cutting technology. A&T Metal Labels is a unit providing copper label processing services, printed aluminum labels, alloy labels applying many modern technologies such as CNC router, laser engraving, UV printing, … ensuring high quality and precision. A&T Label is committed to providing quality products, fast processing time and competitive prices. A team of experienced technicians is always ready to support and advise customers on the most suitable low-cost product label solutions. For more information, please contact below:

A&T INVESTMENT AND TRADING COMPANY LIMITED

✅Website: www.temkimloai.com.vn

✅Email: temnhanat@gmail.com

✅Zalo: https://zalo.me/0907163319

✅Hotline: 0907 163 319